A new approach to canola oil and protein preservation

One researcher’s journey to a breakthrough in oil extraction.

One researcher’s journey to a breakthrough in oil extraction.

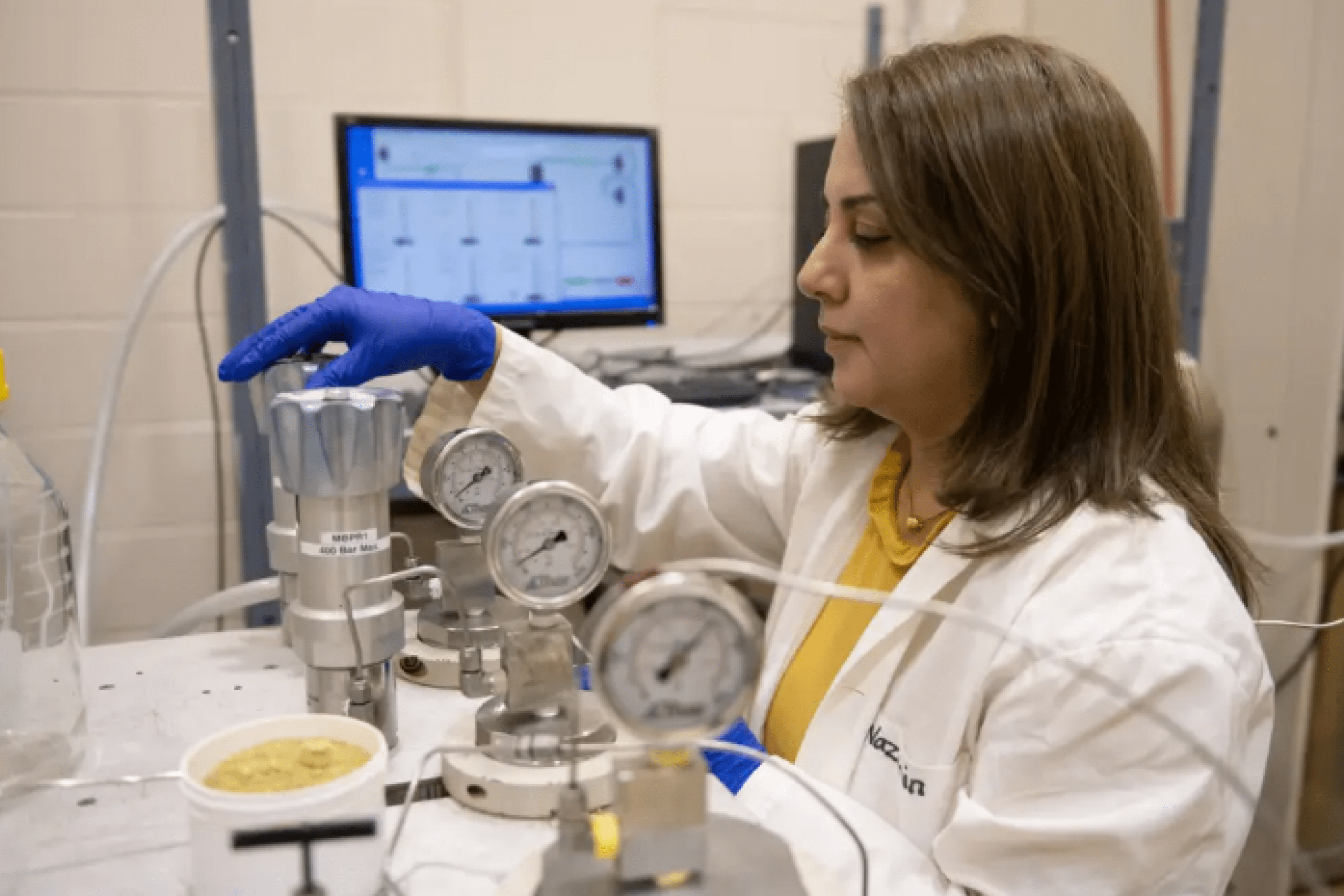

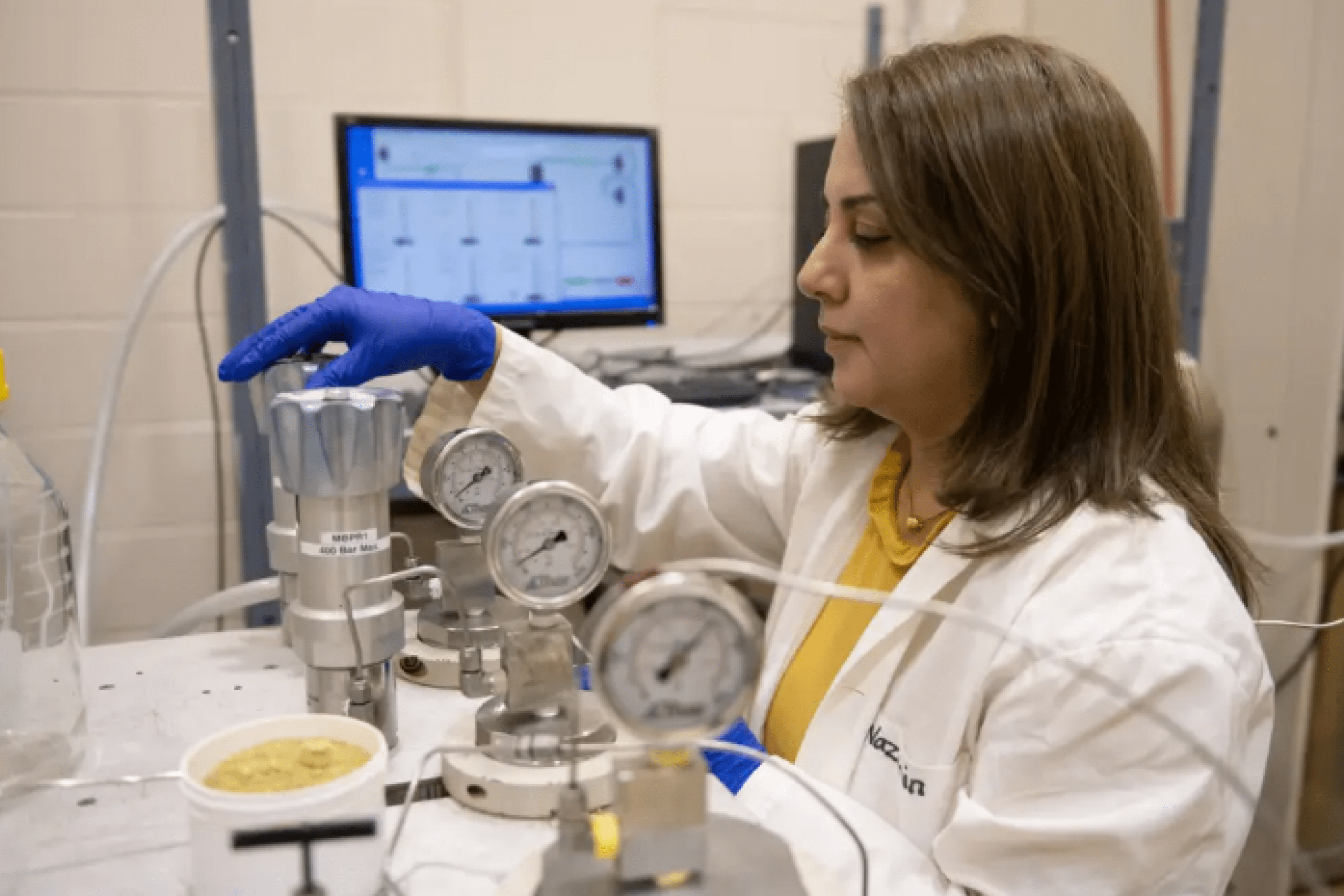

A groundbreaking innovation in canola oil extraction, developed by Dr. Nazanin Vafaei, a postdoctoral researcher at the Richardson Centre for Food Technology and Research, is set to transform the industry by reducing waste, and enhancing efficiency. Her pioneering work using a low-temperature method that preserves the quality of both oil and protein-rich canola meal byproduct.

Vafaei’s groundbreaking research to optimize this underutilized method for sustainable food processing has earned her the prestigious Mitacs Outstanding Innovation Award.

First developed at the University of Manitoba, canola oil is one of the top three food oils consumed worldwide. While traditional solvent-based extraction methods are effective, supercritical fluid extraction operates at significantly lower temperatures which enhances the quality of canola meal for use in functional foods.

This new methodology, developed by Vafaei, first removes a portion of the oil through mechanical pressing, followed by high-pressure CO₂ to extract the remaining oil resulting in an oil-free canola meal. This method preserves protein integrity, making canola meal that is more suitable for high-value food applications such as plant-based burgers, high-protein pasta, and protein supplements.

“Our tests show that canola meal contains 40% protein, making it a valuable ingredient for plant-based foods,” explains Vafaei. “The supercritical fluid method uses only CO₂, a process commonly used for decaffeinating coffee. Applying this method to canola allows us to extract high-quality, expeller-pressed oil while maintaining a protein-rich meal with no oil or solvent residues.”

In addition to preserving the high protein content and amino acid profile of canola meal, tests showed this method had good functional properties, including high water-holding capacity, foaming stability and emulsification ability, crucial properties for developing dairy and meat alternatives.

"This process is practically waste-free, using only CO₂ gas, which can be repressurized and reused. The lower temperature used in our process protects the protein’s natural structure, making the canola meal more functional for food applications," says Vafaei.

"This process is practically waste-free, using only CO₂ gas, which can be repressurized and reused, says Vafaei. "The lower temperature used in our process protects the protein’s natural structure, making the canola meal more functional for food applications."

The next step in Vafaei’s research is to explore scaling up production, with a proposal recently submitted for potential collaboration with the University of Alberta, the University of Guelph and the University of Saskatchewan. If funded, this research will assess the commercial viability and potential industry adoption of the method.

“I congratulate Dr. Vafaei on this successful innovation and her recognition with the prestigious Mitacs award,” says Dr. Mario Pinto, Vice-President Research and International. “By following her passion, she has shown that environmentally sustainable practices can be achieved while also increasing potential economic gain. This has tremendous potential to reshape agricultural practices here in Manitoba and around the world.”

A Vision for Global Impact

Beyond the scientific and technological advancements, Dr. Nazanin Vafaei is driven by the potential global impact of her work on sustainable food production.

“Our canola oil has a lovely roasted nut aroma and a bright, golden color,” says Vafaei. “Because we use a combination of expeller pressing and supercritical fluid extraction (SFE) at lower temperatures, the seeds don’t burn, and we’re able to retain more natural antioxidants.”

By preserving protein integrity and enhancing nutritional quality, her method ensures that canola meal remains a high-value ingredient for plant-based food applications worldwide.

"We’ve demonstrated an exciting proof of concept—our process maintains the full amino acid profile of canola protein while increasing antioxidant levels, thanks to the gentle extraction conditions," says Vafaei.

Looking ahead, Vafaei hopes this innovation will inspire broader adoption of sustainable processing methods in the food industry.

“I am truly honored to receive the Mitacs Award, and I hope the success of this project will encourage more environmentally conscious developments—not just here in Canada, but globally.”

With the growing demand for plant-based proteins and sustainable food solutions, Vafaei’s work has the potential to reshape food production practices while reducing environmental impact worldwide.

Research at the University of Manitoba is partially supported by funding from the Government of Canada Research Support Fund.

New tech fights bacteria

New funding for accessible tools announced earlier this year.

A new cutting edge in disease prevention.

The Dean's Prize recognizes exceptional academic achievement, strong leadership skills and notable personal service.