Innovation Success: From smelly hockey gear to safer surgeries

New tech fights bacteria

New tech fights bacteria

Hockey socks, football pads and sweat-soaked jerseys are all surfaces where bacteria have settled in and caused a stink. The bacteria causing these unpleasant odours is, however, part of a much larger problem.

In hospital corridors, there is a life and death battle to keep harmful bacteria from infecting vulnerable patients. In North America, that often means using disposable gowns, surgical drapes and covers. These single use items may be sterile, but they also create mountains of medical waste.

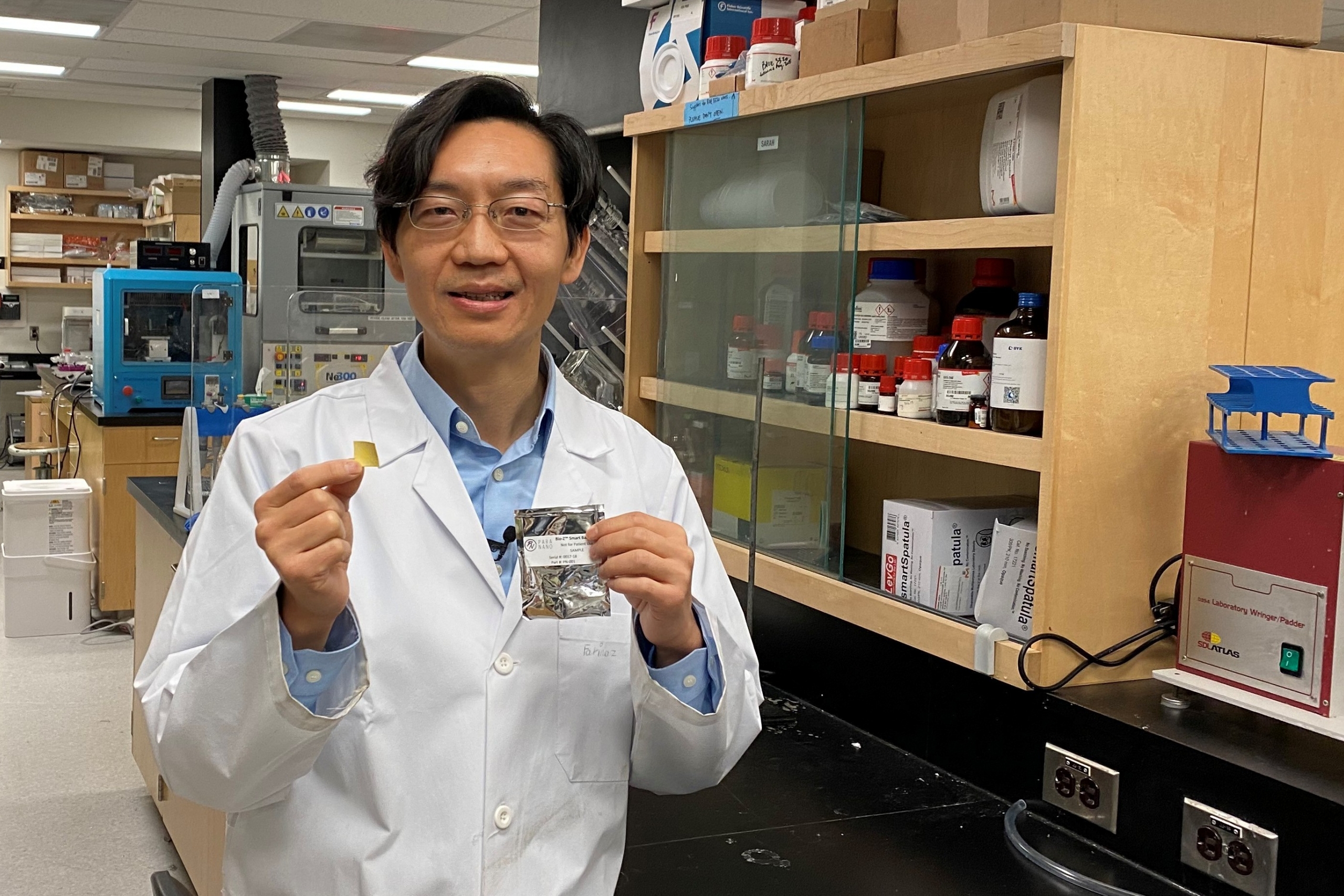

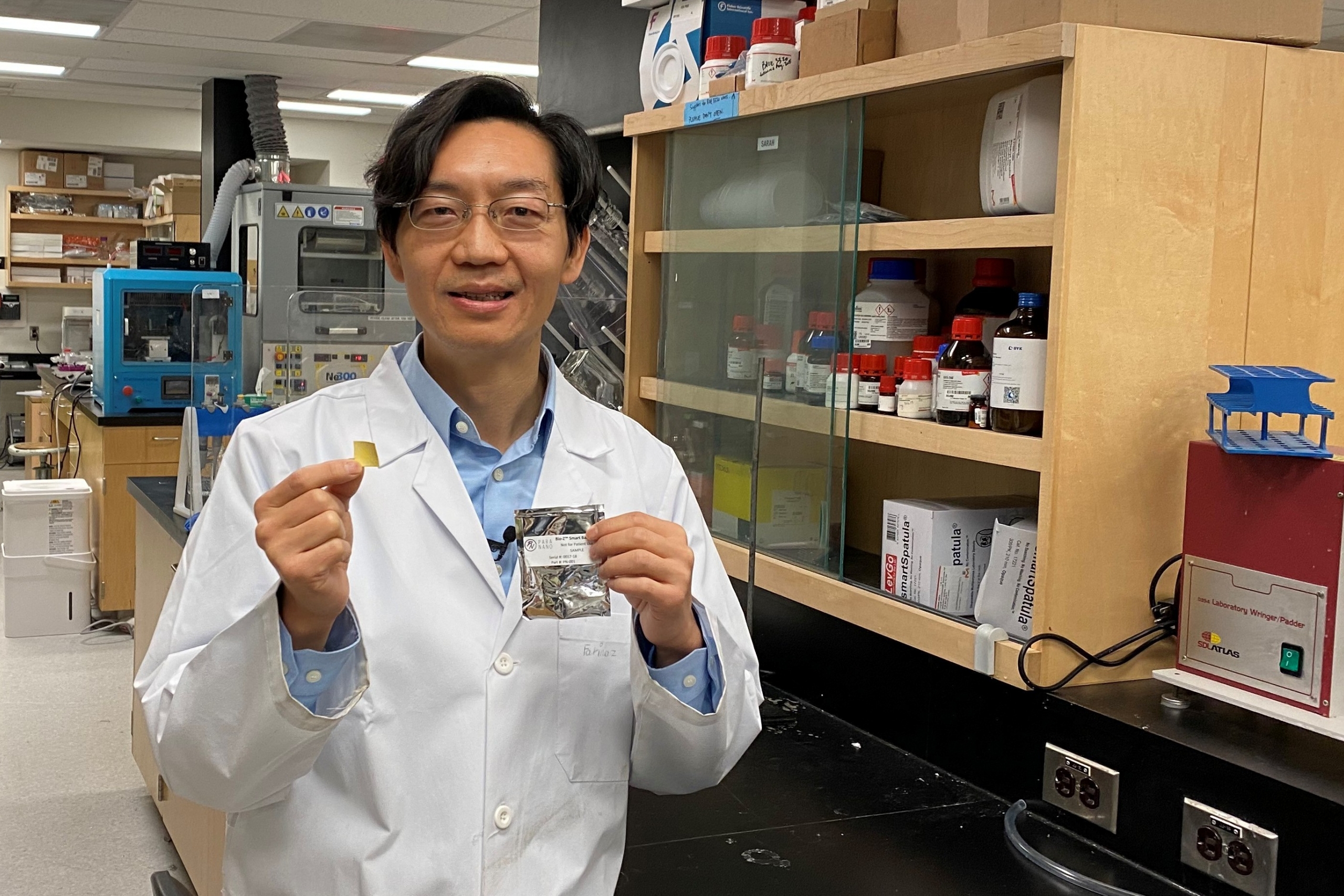

This is where UM’s Dr. Song Liu can help.

Liu has been researching antimicrobial resistant finishes for textiles since he was a PhD student in 2003 at UC Davis. Now, as a professor of polymer science and engineering in the Price Faculty of Engineering and director of UM’s Biomaterials Synthesis and Surface Engineering Laboratory, he focusses on developing durable and versatile finishes and nanotechnologies for fabrics and hard surfaces.

“What matters most to me is translating our discoveries into technologies that make a tangible difference and solve problems in hospitals, homes and in other settings where sterile surfaces are required,” says Liu.

Anti-microbial finishes first appeared commercially in the 1980s on socks and underwear but were not durable and easily washed away in the laundering process. Liu’s modern antimicrobial finishes are durable and rechargeable when exposed to chlorine bleach, making them ideal for medical applications and anywhere needing a sterile surface.

Liu’s inventions have been successfully commercialized with numerous patent applications, six granted patents and three licencing agreements. Thanks to its versatility on both hard and soft surfaces, his finishes can be used on a broad range of products – from food processing and medical applications to sports equipment and in the fashion industry.

UM provided support through research grants, lab space, legal and commercial strategic partnership guidance to translate Liu’s research into real-world applications.

“It’s incredibly rewarding to see an idea that started in our lab actually being used to make environments safer and reduce waste,” said Liu.

Liu’s antimicrobial finish patent was first licensed to a UM alumni-run company Exigence in 2014 and has since be re-licenced to X-Halochem Technologies, Inc. They are developing industry coatings for food processing, packaging and health care uses. Focussing on smart functional clothing technology, X-Halochem is working with the defence and medical sectors to provide antibacterial, odourless and comfortable clothing.

Since 2018, UM has licenced several patents to Paranano labs, an Oklahoma-based company specializing in wound care technology. ParaNano and Liu have developed new antibacterial nanofibers for a wound dressing that change colour and release biocides to tackle infections. This groundbreaking product recently gained FDA approval and will be available commercially this fall under the WoundCue™ brand.

“Dr. Liu brings visionary thinking, deep scientific expertise, and a genuine passion for innovation that’s driving impact far beyond wound care. We’re proud to have Dr. Liu as both a partner and a true thought leader shaping the future of healthcare,” says Chelsea Luxen, CEO and cofounder of ParaNano Woundcare, LLC.

Surgeons and healthcare providers are continually asking for innovative ways to monitor and treat patients with wounds.

“Good wound care should be directed care. Diagnostic tools direct that care. The WoundCue™ will have the capacity to do that,” says Dr. Ronald Scott, MD, Texas Health Resources and WoundCare development advisor. “It could direct the clinician at the point of care, to take appropriate steps in a timely fashion for better outcomes.”

Through ongoing market research and a NSERC Lab2Market funded study, the team identified compelling opportunities for development.

They are listening to what the market is telling them and have several targeted products under development for future commercial purposes. These include:

Special finishes for sporting equipment to help stop bacteria from growing and causing foul odours on the soft and hard surfaces.

Non-leaching, safe and renewable applications for sterile food processing surfaces like counters and conveyor belts to help eliminate food borne bacteria.

Offering hope to patients suffering from burns or chronic wounds. Liu’s team is working to develop next-generation skin substitutes that promote natural tissue regeneration without scarring.

“Through sustained collaboration, strategic partnerships and technology transfer, we continue to help bridge the gap between laboratory innovation and clinical application,” says Liu.

The team is actively seeking strategic partners to help scale up manufacturing and deployment of the technologies developed in UM labs. For more information on partnership opportunities, please contact: partnerships@umanitoba.ca

For more information on turning research into impact through partnership and collaboration, visit our website.

This article is part of a series celebrating UM-backed startups that are turning breakthrough research into solutions for our communities and economy. Discover the other stories in the series Innovation Success: UM-backed tech promises early diagnosis of chronic kidney disease and Innovation Success: The startup fighting viruses you can't see

For nearly 150 years, UM has transformed lives through groundbreaking research and homegrown innovation. We push the boundaries of knowledge and do the hard work here in Manitoba to move our community and the world forward. With a spirit of determination and discovery, we are shaping a better future for our province and beyond.

Research at the University of Manitoba is partially supported by funding from the Government of Canada Research Support Fund.

New funding for accessible tools announced earlier this year.

A new cutting edge in disease prevention.

The Dean's Prize recognizes exceptional academic achievement, strong leadership skills and notable personal service.

We asked Mercedes Garcia-Holguera in UM's Faculty of Architecture.